PLAATO INSIGHTS PLATFORM

Unlock Your Beverage Production Data

With AI

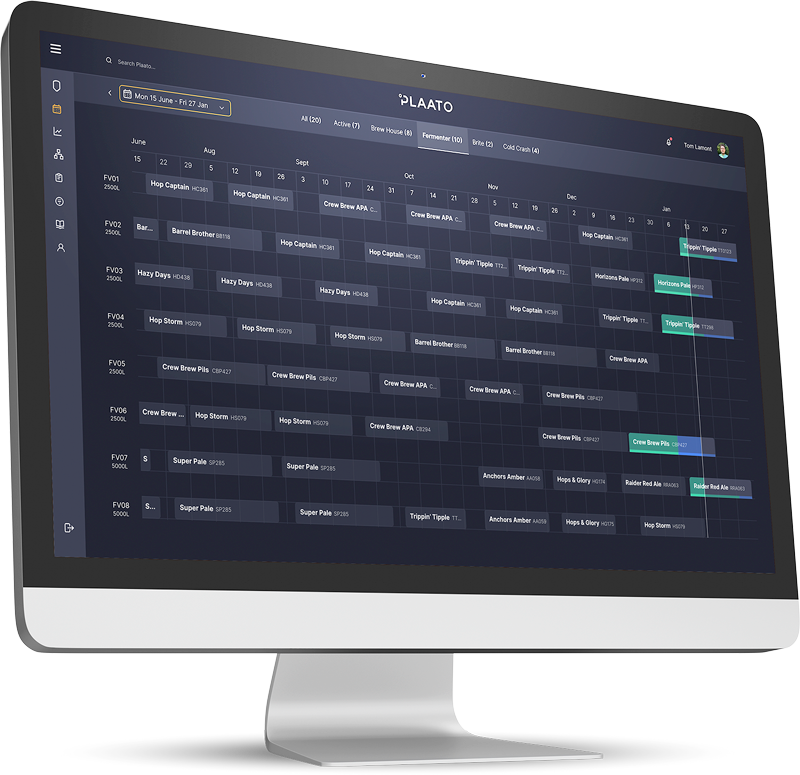

Most beverage facilities have plenty of data — it’s just scattered across PLCs, spreadsheets, sensors, and teams. PLAATO unifies it into one operational view, so you can spot issues earlier, reduce losses, and improve consistency.

400+ manufacturers in 38 countries have

grown their business with PLAATO

Elevate beverage production with PLAATO

PLAATO helps beverage producers turn fragmented production data into real-time insight — across the entire production process, start to finish.

With a unified view of performance, quality, downtime, and yield loss, teams can act earlier and run production with fewer surprises.

Unlocking insights: How PLAATO Insights supports beverage producers — example walkthrough

PLAATO collects data from your equipment and systems, then makes it usable in one place — so bottlenecks, deviations, and losses are visible while there’s still time to respond.

PLAATO’s beverage production software solutions

Common beverage manufacturer pain points

Beverage production is rarely missing data — it’s missing alignment. When information is fragmented, decisions get delayed, and small deviations turn into waste, downtime, or quality holds.

Beverage Software Integration

For beverage facilities running one or many PLCs, PLAATO connects to existing control systems and pulls production data into one unified Insights platform.

Installation is designed to be simple and non-intrusive — so teams can start proving value without replacing current systems.

Key areas PLAATO can help with

Avoid issues before they grow, catch anomalies instantly, and reduce manual work through automated automated data collection and performance analytics.

Increase Throughput

Shorten cycle times without compromising quality. Detect bottlenecks and reduce idling across production, processing, and packaging.

Protect Product Quality

Improve consistency with better visibility into deviations, batch differences, and process drift — and faster root cause analysis.

Reduce Downtime

Spot equipment drift earlier with alerts and performance trends, so downtime is less disruptive and maintenance is more predictable.

Improve Yield

Identify where product is lost across transfers, holds, rework, and changeovers — and support practical improvements with real data.

Typical improvements include higher throughput, fewer deviations, less downtime, and reduced loss — depending on process and baseline

Benefits of PLAATO’s Beverage Production Software And Platform

PLAATO gives beverage teams a clearer view of how production actually runs — so improvements are based on measured reality, not assumptions.

-

Monitor key stages and signals as production runs, so teams can respond earlier.

-

See where flow slows down across stages, and focus improvement work where it will matter most.

-

Automate data collection and reduce time spent compiling logs, spreadsheets, and reports.

-

Beverage producers can scale production confidently with real-time and historical data across every stage of production — improving efficiency, consistency, and quality as operations grow.

-

Bring sensor, PLC, and operator data together so teams work from the same operational picture.

-

Compare runs, identify what changed, and support faster investigation when quality deviates.

-

Connect to existing systems without a disruptive rip-and-replace approach.

-

At PLAATO, we are committed to ensuring your data is protected when you use our beverage platform. That’s why we comply with relevant data protection laws and regulations. All data that you provide, including data collected by our sensors, is collected securely over robustly encrypted channels. We also carry out regular penetration testing and ensure industry best practices in everything we do to prevent unauthorised access and give our clients confidence.

Contact us today for more information on how we collect, store, and protect your data. -

PLAATO ensures that our products meet industry regulations, standards, and quality frameworks so that, when you use our products and services, your compliance needs are met.

What customers are saying about PLAATO

"I've really appreciated having PLAATO for the last year as it's enabled me to have remote visibility, and ensure my ferms are on track. I've been able to experiment with different yeasts and see exactly what's happening in the tank as a result. It's been important to see that the graphs are the same/similar each time as I then know my process is faultless."

The Walrus Distillery, David Robertson

Why choose PLAATO?

PLAATO provides a single operational view across your beverage production — helping teams improve consistency, reduce waste, and make decisions earlier.

Get your production data in one place, where it’s easier to monitor, compare batches, and identify what’s driving performance changes.

We work closely with production, engineering, and quality teams — because improvements only stick when they fit the way the facility actually runs.

FAQs

-

Beverage production software helps teams monitor production performance, track key process signals, and unify data across stages — so issues are easier to detect and improvements are easier to prove.

-

Operations, production managers, engineering, and quality teams — especially where data is spread across multiple systems and decisions are being made with partial visibility.

-

PLAATO connects to your existing PLCs and relevant data sources and brings the data into one platform. The goal is to add visibility without changing your current control setup.

-

Returns typically come from reducing downtime, preventing quality loss, improving throughput, and reducing product loss — depending on your process and baseline performance.

-

Many teams start small to prove value, then expand coverage across additional lines and process stages once the data is delivering consistent wins.