PLAATO INSIGHTS PLATFORM

Unlock Your Dairy Production Data With AI

At PLAATO, we help dairy producers work smarter by turning production data into real-time insight — reducing losses, improving consistency, and increasing throughput across every processing stage.

400+ manufacturers in 38 countries have

grown their business with PLAATO

Elevate dairy production with PLAATO

PLAATO helps dairy producers turn fragmented production data into real-time insight — across fermentation, processing, and quality-critical steps.

From cultured products to liquid dairy, PLAATO provides a single view of performance, consistency, losses, and process drift — so teams can act before issues lead to downtime, waste, or quality risk.

Unlocking insights: How PLAATO Insights supports industrial dairy, food & beverage facilities

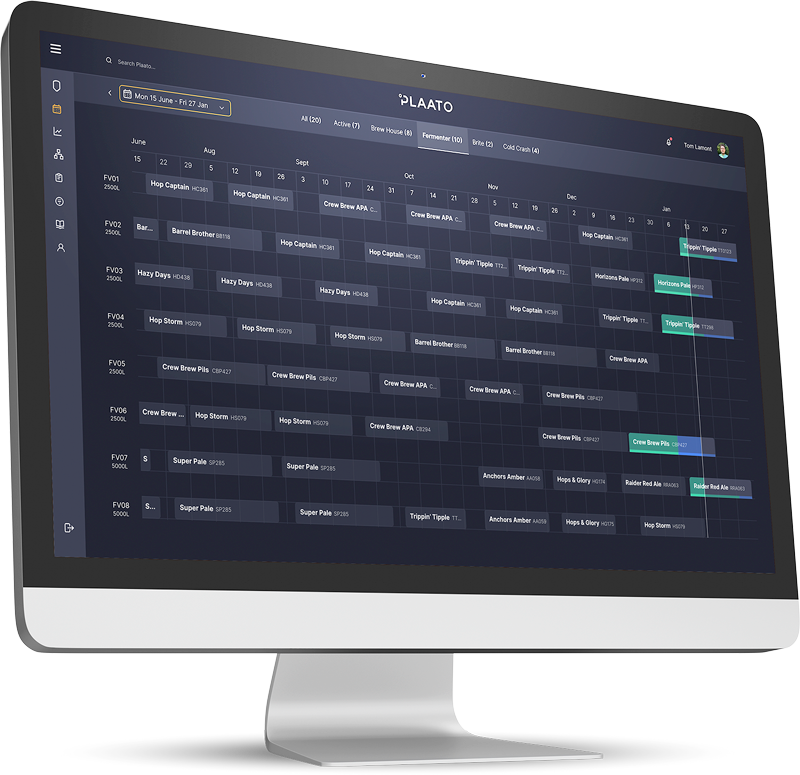

Through one small device, PLAATO Insights collects all your data across your entire production site. It then analyzes it and enables you to spot bottlenecks, identify equipment issues, meet sales demands, and more: 24/7, 365 days a year. With all your data visible in a customisable dashboard.

Dairy production software solutions

Common dairy manufacturer pain points

Dairy production brings complex challenges — from inconsistent quality and fragmented data to high energy costs and inefficient temperature control. Each pain point faced can lead to high costs, batch delays, and inconsistencies. However, with PLAATO’s production management software, you can see and prevent issues in real time. Here’s where we can help.

Dairy Software Integration

For dairy facilities running multiple PLCs across processing, fermentation, and packaging, the PLAATO Edge gateway connects seamlessly to each system, delivering all your process data into one unified Insights platform.

PLAATO integrates with existing dairy production systems — from sensors and PLCs to lab and manual data — creating a unified, real-time view of performance without replacing your current stack.

For more information on equipment requirements or setup, please contact us today, and our dedicated team will be happy to help.

Key areas PLAATO can help with

Avoid issues before they grow, catch anomalies instantly, and reduce manual work through automated, intelligent data tracking.

Increase Throughput

Shorten cycle times without compromising quality or safety. Optimizes sequences, speeds up processes, cleaning, detects bottlenecks, idling, over-production and more. Reducing waste and improving yield.

Protect Product Quality

Monitor critical parameters and respond before deviations escalate. Detect drift early across fermentation and processing stages. Improves process stability from end-to-end.

Reduce Downtime

Identify bottlenecks, yield loss, and inefficiencies in real time. Delivers early warning analytics on your equipment, as well as predictive maintenance.

Benefits of PLAATO’s Dairy Production Software

With PLAATO’s dairy software, you can experience a host of benefits when it comes to the production process, product quality, and the efficiency of your operations.

-

PLAATO provides a real-time overview of every stage of the production process so you can continuously monitor and make proactive decisions that avoid big problems.

-

You can identify slowdowns in the production flow with bottleneck detection. This can save time and help you make decisions that improve workflow.

-

With automated data collection and analysis, manual checks are reduced and operations are streamlined.

-

Dairy producers can scale production confidently with real-time and historical data across every stage of production — improving efficiency, consistency, and quality as operations grow.

-

PLAATO brings all your data into one place and enables real-time as well as historical data so you can track trends, compare batches, and see how you can make improvements. It’s also perfect for cross-team visibility, so everyone works off the same data, no matter which area they’re involved in.

-

PLAATO software can easily integrate with your existing systems, providing a seamless transition into new workflows.

-

At PLAATO, we are committed to ensuring your data is protected when you use our winery software. That’s why we comply with relevant data protection laws and regulations. All data that you provide, including data collected by our sensors, is collected securely over robustly encrypted channels. We also carry out regular penetration testing and ensure industry best practices in everything we do to prevent unauthorised access and give our clients confidence.

Contact us today for more information on how we collect, store, and protect your data. -

PLAATO ensures that our products meet industry regulations, standards, and quality frameworks so that, when you use our products and services, your compliance needs are met.

What customers are saying about PLAATO

"I've really appreciated having PLAATO for the last year as it's enabled me to have remote visibility, and ensure my ferms are on track. I've been able to experiment with different yeasts and see exactly what's happening in the tank as a result. It's been important to see that the graphs are the same/similar each time as I then know my process is faultless."

The Walrus Distillery, David Robertson

Why choose PLAATO?

PLAATO gives you real-time visibility across every stage of production to improve consistency, optimise batches and reduce waste while maintaining a high-quality product every time.

Get all your production data in one place, where it’s easy to manage and compare batches and make informed decisions that improve future production.

We have deep expertise in dairy manufacturing technology, so let us help you make better decisions. Get in touch to see how we can help your operation.

FAQs

-

Dairy production software is used by operations teams, production managers, and quality assurance specialists in dairy manufacturing plants who want real-time visibility and control over their processes.

-

Our dairy production software platform integrates seamlessly with sensors, tanks, and other production hardware, as well as ERP and SCADA systems.

-

Dairy producers often see returns through reduced downtime, lower product loss, improved production planning, and more consistent product quality.

-

Solutions like PLAATO are fully scalable. Whether you’re a medium to large or global manufacturer, PLAATO’s dairy software can grow with your production needs.

-

Dairy production software helps producers of dairy based products monitor, control, and optimise the production process, from start to finish.

Let’s talk!

Be the master of your dairy production with PLAATO

Book a call to get to know our products better and to find what’s the right fit for you and your goals right now, or for the future.